September 1, 2024: Rattle Battle 4

The quest for silence is neverending.

One year ago I took on the challenge to defeat noisy gremlins in the cabin interior once and for all ... at least the very noticeable ones. And overall I was successful. The not-so-well-planned restoration project brought me back closer to the brand-new-car experience.

But after driving around with a much-improved quality of life for the last year, the human ear discerningly picks up on the remaining vibrations which were previously after thoughts but are now more pronounced. The old saying of 20% of the problems require 80% of the work - well, now I'm at that stage where 5% of problems require 95% of the work. Worth it? Probably not to most people.

But I'm not most people. The First. Three. Attempts made a massive difference but sometimes you get picky, so the hunt continues...

And there I was at it (once again) pulling off the door panels and digging into the front dash for the umpteenth time. The objective this time around was to decompose the door panels down to the individual pieces wherever possible, operating on the assumption that any two parts which were molded or fabricated separately which end up mating next to each other in final assembly is a possible source of vibration which must be reckoned with. These contacts points are opportunities for muffling by inserting thin foam between them to minimize any direct rubbing and rattling against each other as the car rolls over bumps, flexing the body/frame, and thus translating them downstream to parts movement where the pieces have also likely warped over time due to thermal fluctuations and other wear and tear.

Take no prisoners.

Peel back the onion and you get to see more screws to be loosened.

An example of the upper trim piece of the door panel where people naturally rest their arms. The public Tesla Model S Service Manual doesn't seem to even mention this.

The rear door variant.

The door pull cup comes into two halves.

The other half is attached to the arm rest piece, which itself can be broken further down.

The fancy aluminum trim is attached via plastic-molded threads. Be very careful with these while loosening the equally-fragile plastic nut. It's super-easy to sheer these off. I've broken a couple in the process. I recommend not using a power screwdriver.

A frustrating issue is that the pull cup is melded with the aluminum trim, which itself is simply a thin layer that's wrapped around a plastic core and the aluminum is crimped over at the edges. I don't know how to separate these pieces any further.

And this is one area that I've not successfully devised a way to prevent squeaking and rattling. Squeeze on the door pull a bit and it's noticeable.

It took several hours per door panel to properly cut individual small foam pieces to shape in order to ensure every mating/contact point has dampening between every individual part while also not wasting material.

Now onto the dash, particularly the driver's side where I had yet to fully break things down including the carbon fiber trim pieces, the cover around/below the steering column, instrument cluster bezel, etc. I bought an air wedge set just for this purpose to push the top dash pad away from the trim pieces (and to also expose areas directly underneath the pad cover where plastic-on-plastic contact can occur).

Here's the driver's side inner vent unit and the bezel.

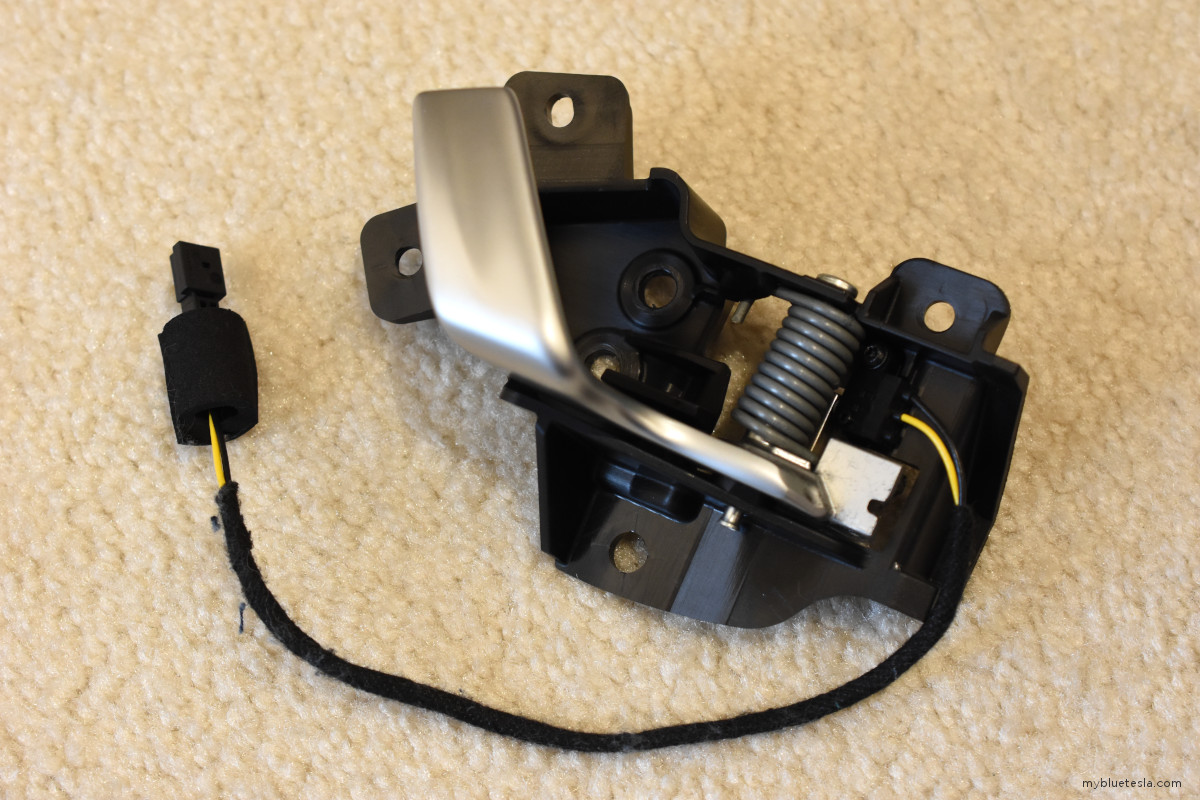

The underside of the vent unit has mechanisms supporting the movement of the fins, but these are also points where rattles occur. Some creative wedging of carefully cut-out foam pieces (such as between the gear teeth) alleviated most of the concerns.

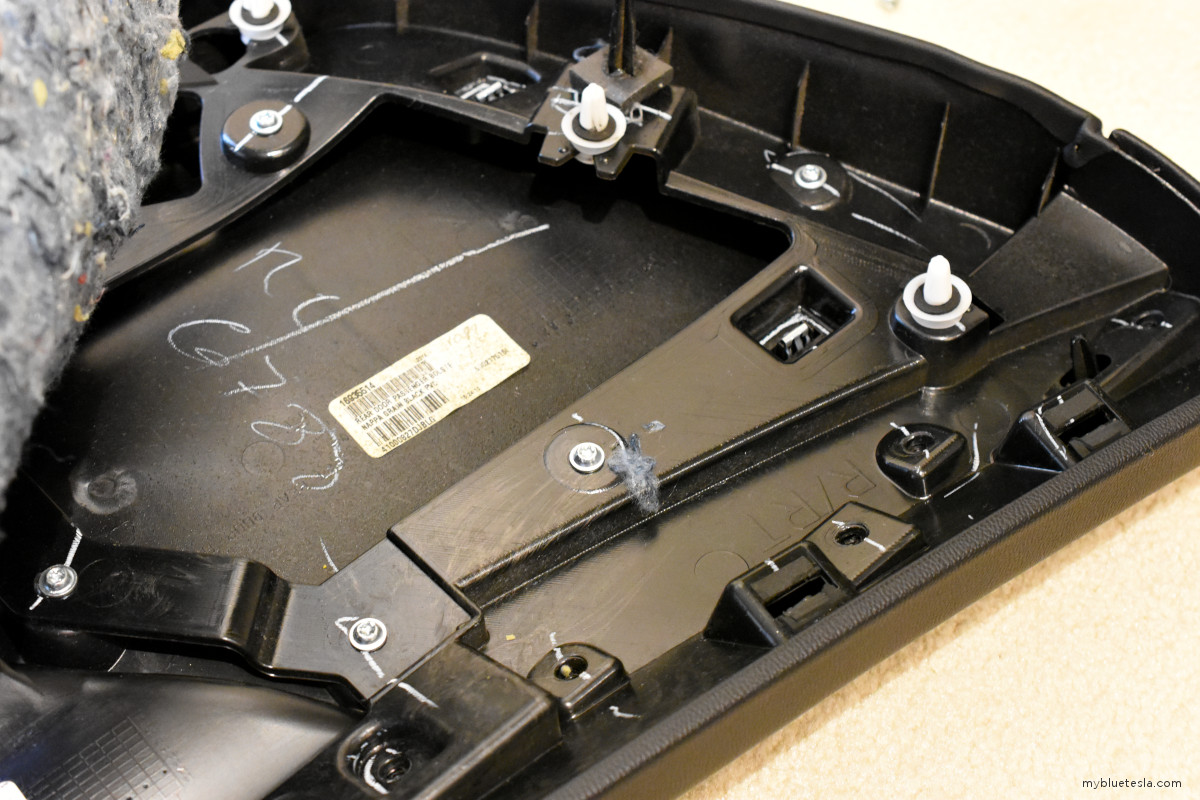

The rear of one of the carbon fiber trim pieces. Note - these metal clips which insert into the rectangular openings of other parts are also rattle-prone, and these loosen up and/or get mangled over time as you remove parts from their resting place, thus wiggling a bit and that movement causes bounce between the metal clips themselves and the plastic mounts they're sitting on. Foam mutes this effectively, although it's real finicky work to wedge them into the right places. Sometimes tweezers are needed.

See that square cage-nut looking thing beneath the instrument panel screen? Yeah, that's not locked in place and can be a source of noise. I had to wedge a very thin piece of felt on one side to minimize its potential to jiggle in place.

I fear this has become a never-ending obsession of mine, but Big Blue is almost 10 years old and it's now a personal challenge to see how long I can keep this car going. There's nothing else compelling enough on the market prompting me to upgrade, so preserving what I have is now a mission statement.